How to maintain care of the excavator slewing part?

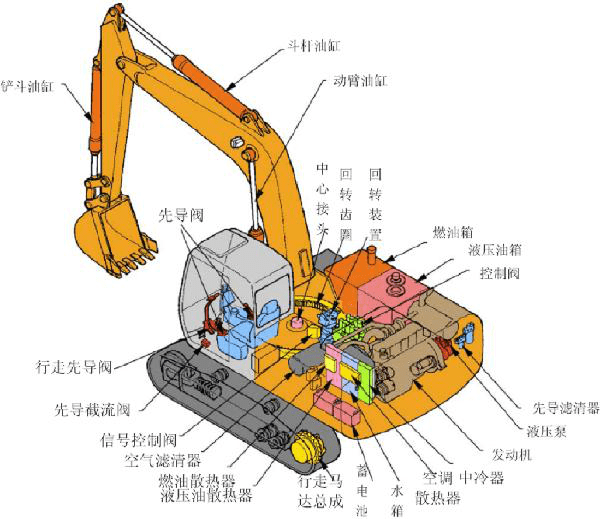

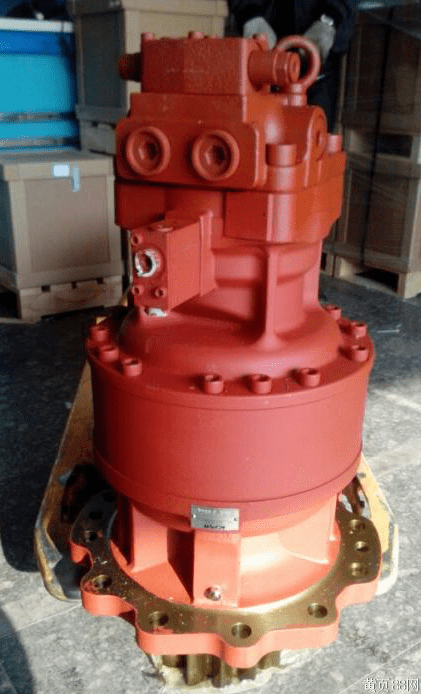

The excavator swing part consisting of motor, reducer, ring gear, a centering point of rotation, etc. How to maintain the excavator slewing part on daily? Let’s take a look!

Need to pay attention to the usual maintenance and repair:

The first one is the excavator slewing bearing part. Observe the lubrication of the large ring gear and the use of the ring gear.

In the operation of the excavator, the dust ring at the center of the swivel will have various aging problems with the increase in the number of times of use and time, such as causing oil leakage, water accumulation, etc., which are generated or used for the use of the slewing mechanism. Or small impact.

1.In the usual maintenance and repair, the lubricating oil of the rotating large turntable gear is inspected and replaced every year or every 2,000 hours. About two barrels (36L) of butter is added to the 20-ton machine. The cover next to the base of the boom should be opened periodically for inspection and handled as soon as possible.

2. The frequency of inspection and replacement of the lubricating oil on the large rotary table is different. The slewing bearing is recommended to be lubricated every 250 hours, and the oil is sprayed up and down at the same time. In this process, the machine is also rotated, and every 15 degrees is filled with a shot of lubricating oil. .

Of course, the frequency and intensity of use of each excavator are not the same, and the lubrication cycle is adjusted appropriately according to your own situation. It should also be noted that the lubrication cycle should not be too short, otherwise too much oil in the bearing will break the dust ring, causing oil leakage, and impurities will be mixed into the bearing, which will affect the normal use of the excavator.

3. The frequency of lubricating oil replacement at the swing motor of the excavator is between the first two and is maintained once every 1000 hours. Observe the amount of lubricating oil from the dipstick. When abnormal conditions are found, check for leaks.

In addition to the daily maintenance of the above parts of the excavator’s slewing bearing, it is also necessary to regularly check the slewing bearing dust ring and the ring gear bolt for damage or looseness. It is necessary to find some of the fine cracks in time, which may be covered by the soil generated during the work process, but these subtle places may cause the turntable to crack, affecting the working efficiency of the excavator and the service life of the excavator’s swing device.

Post time: Apr-22-2020

![V3LSF(]DB2JT36~HVA}%)U4Y](https://www.86dena.com/uploads/ab4b8fba.png)