Repair of the most common minor faults of excavators! / The excavator fails to start, first try to repair by yourself or ask for help directly? / Master this, eliminating unnecessary repair costs

Mastering some excavator maintenance and repair skills should be the skills you need to be a good excavator driver. In this way, you won’t panic when there is a small failure, and you don’t know what to do, directly ask the repairman to see. In addition to increasing time and money costs, it is still a waste of resources.

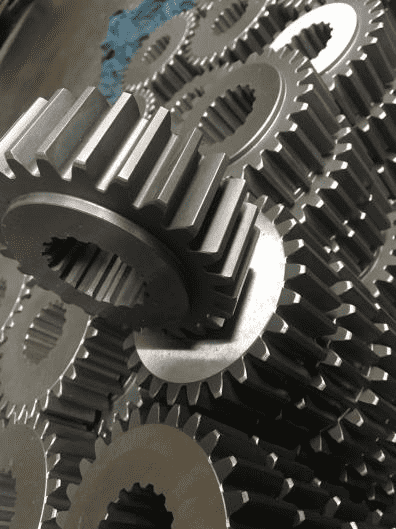

For example, the replacement of gear oil, the exhaust of air from the filter element, etc., some simple methods have been mastered, which can improve our working efficiency and also extend the service life of the excavator.

What I want to share today is the problem often encountered when operating excavators-unable to start. If it continues to fail to start, it may be a problem with the engine itself, not something the driver of the excavator can solve.

But if it can’t start for a while, you can check the possible causes yourself. There are two possible reasons why such a temporary engine cannot be started: one is the electricity on? The other is the oil?

The following is a brief list of troubleshooting ideas:

1.There is no sound when trying to start the excavator motor, that is, the power is not turned on. It is recommended to check the battery for bad contact or burnout.

2.The motor is started, but the speed is slow and the sound is different from usual, indicating that the battery is not enough.

If you can, monitor the power generation. Under normal circumstances, you need to replace the battery.

3. Start the motor, the speed and sound are normal, but the engine cannot start, indicating that the oil can not reach, it is recommended to clean the pipeline and check whether there is a block.

Usually the points that are easily blocked are small strainers at the bottom of the diesel tank and at the hand pump.

It is also possible that air is introduced when the filter element is changed. It is recommended to loosen the exhaust screw a little and pump oil with a hand oil pump.

4. The driver of the excavator may also encounter the opposite problem: the flame cannot be turned off and the key cannot be pulled out.

This is usually caused by the flameout cable not being pulled,

Open the engine cover of the excavator and push the cable head into place to turn off the flame.

5.There is also a case: the engine is easy to start in the morning or when the temperature is low, and when the water temperature rises to a certain temperature, the engine will not start again after the flame is turned off. You must wait until the engine cools down before restarting.

This is what happens with many old machines, usually because of poor diesel quality and damage to the diesel pump.

In this case, the oil pump needs to be calibrated, and the work of the oil pump needs to be completed by professionals.

The above points are usually available for troubleshooting, hoping to help more excavator operators.

Post time: Apr-22-2020

![V3LSF(]DB2JT36~HVA}%)U4Y](https://www.86dena.com/uploads/ab4b8fba.png)